Today was a great day to roll the lathe out of the garage and shape a rod handle. Now, RPMs and the grit number of sand paper are not as important as the safety precautions you should take when operating a lathe. Safety glasses are a must, and a paper respirator is not a bad idea. Because your hands and arm are so close to moving parts you have to avoid wearing long sleeves or jewelry. Think safety.

After sanding through the hardened epoxy beads and leveling the cork rings you can begin to slowly uncover your hidden shape. When finished up with the finest grit you can call it done, or choose to use a cork sealer as I have above. Before applying the sealer you have to clean the finished shape with a wet paper towel. You do this while the rod is still turning. Touch up with a dry paper towel, turn lathe off, and wait. When the cork handle is completely dry you can lightly brush on the sealer, and when the sealer is completely dry you have to turn the lathe on again and touch up with the finest grit paper.

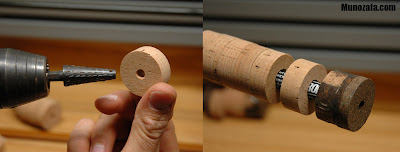

Many rod builders build their handles off the blank. They follow similar steps but turn the handle on a steel mandrill. When the handle is complete it is reamed and glued onto the blank. This process allows for mistakes to be made when shaping and avoids possible damage to the rod blank. Our method does not allow mistakes so we try very hard not to make them.